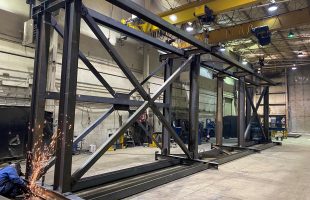

Structural Steel Fabrication Fabricating Steel, Structuring Solutions

For nearly two decades, Furlong Steel’s CWB-certified structural shop has focused heavily on SAGD and gas plant facilities; but our capabilities don’t end there. Our experience goes beyond the oil and gas market and includes agriculture, carbon capture, renewables, and development projects.

For nearly two decades, Furlong Steel’s CWB-certified structural shop has focused heavily on SAGD and gas plant facilities; but our capabilities don’t end there. Our experience goes beyond the oil and gas market and includes agriculture, carbon capture, renewables, and development projects.

Featuring

- 35,000 square feet of indoor shop space dedicated to structural projects

- Dozens of overhead cranes, from 5T – 35T

- 200-tons per month, proven output of finished steel

- 144,000 square feet (3.3 acres) of yard space

- CWB W47.1 certified

- Plasma table

Common projects

- Skid packages

- Pipe rack modules

- Platform systems

- Ladders and handrails

- Pipe supports

- Pipe shoes

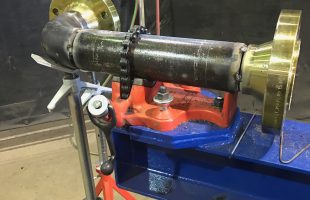

Pressure Piping Furlong Steel alleviates the pressure

Whether you require loose spooling or a full pipe rack assembly, Furlong Steel has the capacity and experience to fabricate your carbon or stainless steel pressure pipe project.

Featuring

- ABSA AQP certification for B31.3 process piping & B31.1 power piping

- ABSA certification for P1 (carbon steel) & P8 (stainless steel)

- 26,000 square feet of indoor pipe shop space

- 15,000 weld inches per month, proven output

- 8,250 square foot stainless steel dedicated shop, with independent equipment and hydro testing

- In-house hydro testing facility

Coatings In-House Industrial Coatings

With a Journeyman Industrial Painter leading our team of painters and sandblasters, Furlong Steel offers a wide range of coating products and services, all in-house and indoors, just steps from the main fabrication building.

With a Journeyman Industrial Painter leading our team of painters and sandblasters, Furlong Steel offers a wide range of coating products and services, all in-house and indoors, just steps from the main fabrication building.

In-House Products & Services

- Endura liners

- Offshore systems

- Mobile spray foam insulation

- Indoor sandblasting bays, for all-weather work

Featuring

- 6,800 square feet of paint & blast space

- Fully enclosed, explosion-proof paint bays

- Can accommodate projects up to 28’ wide & 25’ high

- NACE CIP Level 1 Coating Inspection with full traceability reports

- Paint thickness and ambient atmospheric recording tools

- Controlled, heated airflow with 12+ exchanges per hour

- Access to 135 PSI running pressure

- Airless, air-assist, and agitated conventional spray applications

- 110 PSI operating pressure, using SIL abrasives

What does this mean for your project?

Money savings – save the cost of shipping your project from fabrication to a third-party paint company.

Time savings – all-weather capability means just that – no waiting on weather. No waiting on transportation. No time spent loading your project onto trucks, only to unload them for paint and then load them back up again for delivery.

Efficiency – Your project is painted just steps from the main fabrication facility. This means we are in control and move your project along, on time, on schedule.

Packaging Complete Package Assembly

Sitting on 11.5 acres, Furlong Steel can accommodate large projects with plenty of space for laydown and package assembly. Ideal for pipe rack modules, process skid packages, pump packages, MCC buildings, and more.

Our secure assembly yard is fully equipped with our own hand tools and heavy equipment including:

- Two 15-ton all-terrain cranes

- Two 6-ton carry-deck cranes

- Genie lift

- Portable welders

- Generators

- A heated office trailer